Practice Scenario

Managing Safety Risks in a Construction Site

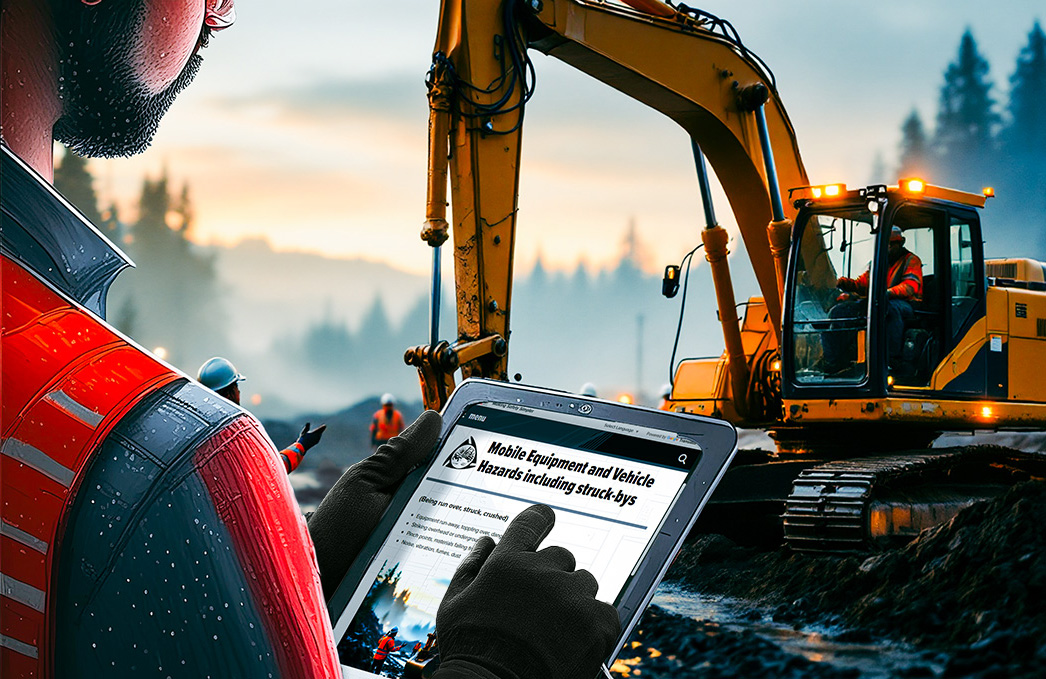

Imagine you are the construction manager at a construction site where a new commercial building is being erected. You've been tasked with ensuring the safety of all workers on site.

Let's walk through the three-step process of Identifying Hazards, Assessing Risks, and Controlling Risks to manage safety effectively.

STEP 1: Identifying Hazards

Workplace Inspection

You start by walking around the construction site and observing how tasks are performed. You notice the following:

- Workers are using ladders to reach high places.

- Heavy machinery like forklifts is in operation.

- Chemicals are being used for cleaning and other tasks.

Consult Workers

You talk to some workers to understand if they have encountered any issues or have safety concerns. One worker mentioned:

- The area near the chemical storage is slippery.

Review Records

You check past incident reports and find:

- There have been two near-miss incidents involving forklifts in the last month.

STEP 2: Assessing Risk

Who Might Be Harmed and How

Fall from heights

Workers may fall while using ladders

Forklift accidents

Pedestrians might be struck by forklifts

Slippery floors

Workers may slip while walking near the chemical storage area

Chemical exposure

Cleaning staff may be exposed to harmful chemicals.

Assess Level of Risk

Using a risk matrix, you rate the risks as follows:

Fall from heights: High Risk

Forklift accidents: Moderate Risk

Slippery floors: Moderate Risk

Chemical exposure: Low Risk

3x3 Risk Matrix (Recommended for most workplaces)

| Hazards are assessed for risk by considering the SEVERITY & PROBABILITY of the hazard causing injury or damage. | SEVERITY | |||

|---|---|---|---|---|

| 3 - LOW CONCERN/STRESS |

2 - MODERATE MEDICAL AID |

1 - HIGH FATALITY/CRITICAL ILLNESS |

||

| PROBABILITY | C - UNLIKELY (Unlikely to occur) |

LOW | LOW | MODERATE |

| B - LIKELY (Likely to happen) |

LOW | MODERATE | HIGH | |

| A - CERTAIN (Almost certain) |

MODERATE | HIGH | HIGH | |

STEP 3: Implementing Risk Controls

High Risk

Fall from heights

Elimination or Substitution

Replace ladders with scissor lifts to eliminate the risk of falls.

Engineering Controls

Install guardrails around elevated platforms.

Personal Protective Equipment (PPE)

Require the use of safety harnesses when working at heights.

Moderate Risk

Forklift accidents

Administrative Controls

Implement a traffic management plan to separate forklifts and pedestrians.

Moderate Risk

Slippery floors

Engineering Controls

Use spill containment platforms in the chemical storage area to prevent slips.

Administrative Controls

Limit access to the chemical storage area to trained personnel only.

Low Risk

Chemical exposure

Personal Protective Equipment (PPE)

Mandate the use of chemical-resistant gloves for cleaning staff.

Monitoring Control Measures

Conduct weekly safety inspections to ensure all control measures are effective. Review and update risk assessments monthly or when new equipment or processes are introduced.